|

|

|

|

|

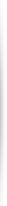

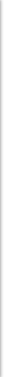

3PL Warehouse

|

Location

|

|

.png)

|

- Pharmaceutical HUB location – Eastern Europe, Latvia;

- International Airport “Riga” (RIX) territory;

- Riga Harbour and Riga city centre - 10-15 minutes drive from Highway Riga-Ventspils and Riga-Liepaja 1minute drive;

- Recently renovated all access roads which are suitable for trucks

See on the map

|

|

|

|

|

Technical characteristics

|

|

|

- Total warehouse space up to 9000 sq m.

- Security system: video surveillance, twenty-four hour guarding, fire alarm, system of limited access;

- Microclimate monitoring – control of temperature and humidity, hygiene and sanitary control, pest control;

- Autonomous heating, up-to-date ventilation and conditioning systems;

- Storage operational procedures (SOP);

- European instructions of quality guarantying: Good Storage Practice (GSP), Good distribution practice (GDP);

- Office connected with warehouses by tunnel;

- According to tenant specification, warehouses premises can be equipped with racks and goods moving and storing facilities;

- 15 gates suitable for all types of trucks and minibuses;

- Total height in storage area – 9,5 m;

- Storage height – 8,5 m (5 levels of storage);

- Acceptance, goods delivery,

expedition section – 1032,2 sq m

- 10 000 euro pallet places with layers and different temperature regimes from +15°С to +25°С ;

- Cold storage facility 750 euro pallet places with temperature regime from +8°С to +15°С;

- 2 refrigerating cameras for 108 euro pallets with temperature regime from +2°С to +8°С and automatic gates.

- In 2011 Astra Logistic Ltd. has successfully implemented modern system of the warehouse management Microsoft Dynamics AX 2009 5.0.

|

|

|

|

|

Temperature Control Warehouse

|

|

In the warehouse available two separated cold storage warehouses with temperature control 8-15°C and 2-8 °C.

|

|

| |

|

Bonded warehouse

|

.png) |

- Astra Logistic Ltd. operates its own bonded warehouse with custom storing capacity for 4000 euro pallets and provides the following related services :

- Storage under different temperature regimes.

- Cargo consolidation.

- Stock management procedures.

- Packaging and labeling of the cargo.

- Custom declarations.

- Production services, insertion of instructions, labeling for secondary packaging.

|

|

| |

|

|

|

Warehouse services

|

|

- Working out and planning of individual logistic solutions;

- Operative delivery of production

from warehouses to airport;

- Unloading and receipt of products for responsible storage;

- Determining of incoming production status;

- Placement at functional zones;

- Palletizing of production;

- Separation and consolidation;

- Goods bundling for clients – selection by the piece, selection by the packing or pallets;

- Production dispatch to carrier;

- Short-term and long-term storage;

- Custom clearance.

|

|

|

In order to ensure full safety and monitoring of product handling, the company takes advantage of the-state-of-the-art technologies in the field of repacking, such as:

|

|

Technologies used in the warehouse

|

|

.png)

|

In order to ensure full safety and monitoring of product handling, the company takes advantage of the-state-of-the-art technologies in the field of repacking, such as:

- Wire mesh containers – which provide higher preservation of freight from a manufacturer to a wholesale seller. The speed of loading – unloading operations will increase at least for 10%, when the wire meshed containers equipped with wheels are used. The stackable wire mesh containers allow making the best use of the usable area.

- Pallet wrapping machine.

- Cooling boxes with thermal elements for inbound logistics (within the Baltic States) and cooling boxes with ice.

|

|

|

|

|

Resource Planning System

|

|

|

To raise the efficiency of work and increase the service quality for our customers, the company has implemented the enterprise resource planning (ERP) system. Reliable operation of the warehouse is guaranteed by a module of the said system – the warehouse management system (WMS).

WMS is a part of complex solution, which provides communication among such elements of system as wireless data communication terminals, the corporate financial system and the computer assisted storing equipment. The system provides flexible integration of various financial modules, as well as compatibility with other software products.

The current warehouse management system is designed for control and monitoring of warehouse activities with the complex functions of distribution. The system is meant for efficient management of warehouse activities and increasing the accuracy of operational execution.

WMS takes into account all storage requirements for the goods arriving in the warehouse. Attention is paid to the temperature conditions, periods of validity, manufacturers, and the best before periods, suppliers, compatibility requirements and other parameters. The accounting system provides continuous monitoring of stock turnover and flow according to the principles of FEFO.

|

|

|

|

|

|

|

|

|

|

|

.png)

.png)

.png)